We always try our best to create the best quality products, every delivery to achieve 100% customer satisfaction.

1.Quality Concept.(图文展示)

Identify customer needs, implement the highest industry standards, continuously improve product quality, ensure customer satisfaction

2.Quality Assurance

Enterprises through IATF16949 and ISO9001 quality management certification system, and QC080000 hazardous substances process management system certification, products through CE, UL, UN, (38.3) and other international certification, and meet the EU RoHS standards

3.Quality Control

R&d quality control, supply chain quality control, raw material inspection, production process and after-sales service and other whole-process control

4.Detection Capability

CNAS certification, with battery materials, cells, battery systems and other comprehensive inspection and testing capabilities

5.After-sale Service

Provide perfect after-sales service, if your product has any quality problems, you can contact us at any time, we will help you solve it as soon as possible.

Quality Management Process

Tianneng Battery Group is committed to improving quality and has formed a unique quality control model of active prevention through years of practical experience. Tianneng has established a strict quality control system and procedures to ensure that customers are provided with satisfactory high-quality products. From material procurement to finished product delivery, from workshop to laboratory, from staff to customers, all levels of inspection are associated with deepening quality management and improving product quality, without omitting any links that may affect product quality.

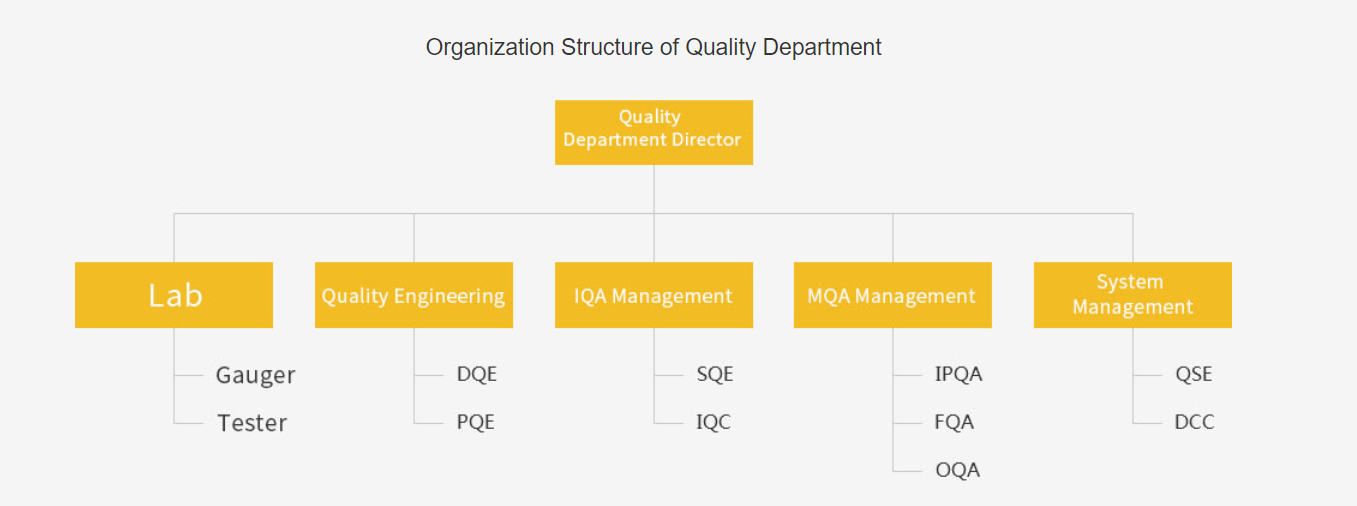

Organization Structure of Quality Department

The strict quality control process includes incoming quality control (IQC, raw material), manufacturing quality control (IPQC, product), and finished product quality control (FQC&OQC, finished product). Products must meet the specific standards of each production node before flowing into the next operation. If the unqualified or defective products occur in the inspection process, the factory will immediately rectify or rework, and record and file them, analyze the causes of the unqualified products, and make a detailed rectification plan according to the problems, so as to reduce the following problems.

On the other hand, it is guarantee of smooth and lean process to prevent problems. All aspects of production should be monitored, including process sampling and determination of compliance. Source management (such as product design evaluation and mass production evaluation) is carried out such as targeted and focused quality control from design and process characteristics, and feedback to product development department or other relevant departments when necessary, so as to improve from the source rather than blindly inspection. Rather than formal engineering, it is more important to sort out customer demands and feedbacks, find and solve problems from the perspective of customers, adhere to the principle of "customer first" and ensure the quality control is effective.

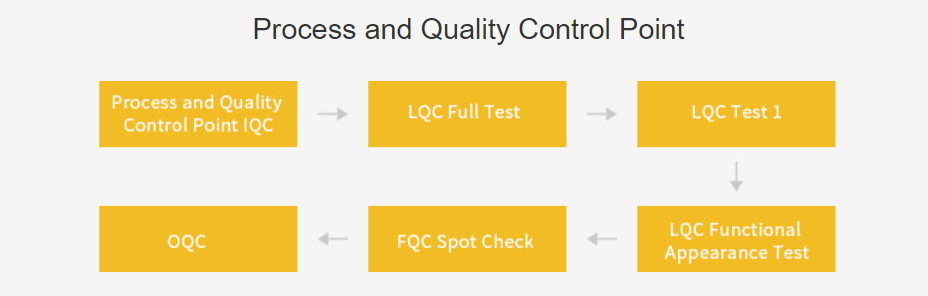

Process and Quality Control Point

While strictly checking materials during production, Tianneng group also carries out regular inspection, calibration and appraisal of production measuring tools, instruments and testing equipment. Tianneng group strengthens daily management to ensure good performance of all appliances and ensure operators are familiar with their correct use methods to avoid serious errors or false data during operation.

Taking the lead in the industry's top production facilities, Tianneng battery adopts 8S management mode, GMP environmental standard and ISO9001 quality management system. Far ahead of the industry, Tianneng battery’s manufacturing and quality control level reaches the world-class level. All our products have passed CE, UL, UN, (38.3) and other international certification, and meet the EU RoHS standards

In the future, Tianneng battery will continue to take honesty as the foundation, strive for perfection, conduct scientific management and actively create a harmonious and win-win situation among suppliers, employees of all departments, shareholders and customers.